Desiccant BreathersRemove Moisture & Particulates from Equipment

Air Sentry desiccant breathers set the standard for contamination control breather technology in 1997, creating new state-of-the-art features that reduced particulate and moisture contamination.

The innovative Air Sentry breather line was the first to integrate check valve technology and the first to offer replacement desiccant/filter cartridges, significantly reducing maintenance costs.

Air Sentry products cover a wide range of application requirements. The line consists of Good (Z-Series & D-Series), Better (X-Series) and Best (Guardian) options designed to meet your specific application and duration specifications.

Find the Best Breather Options for Your Application:

Breather Selector Tool

GoodBetterBest

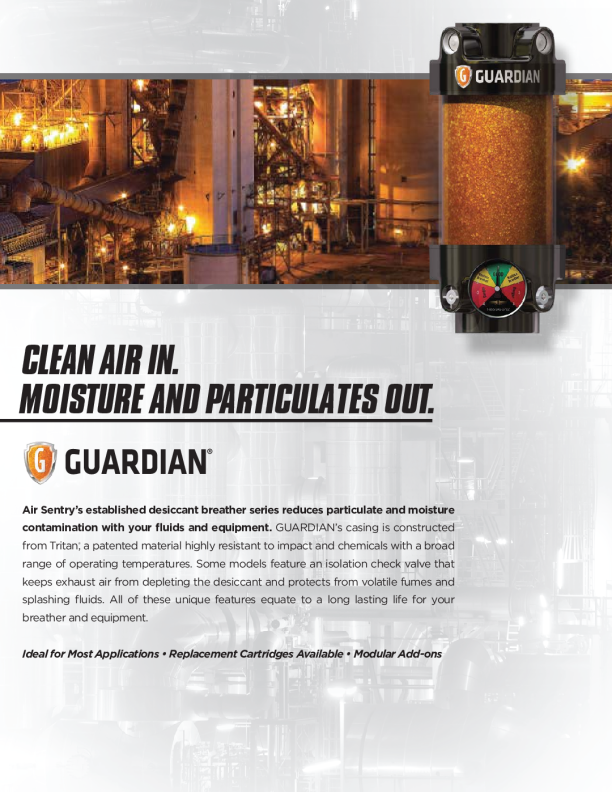

Guardian Series

Ideal for Most Applications – Replacement Cartridges Available – Customizable Modular Add-ons

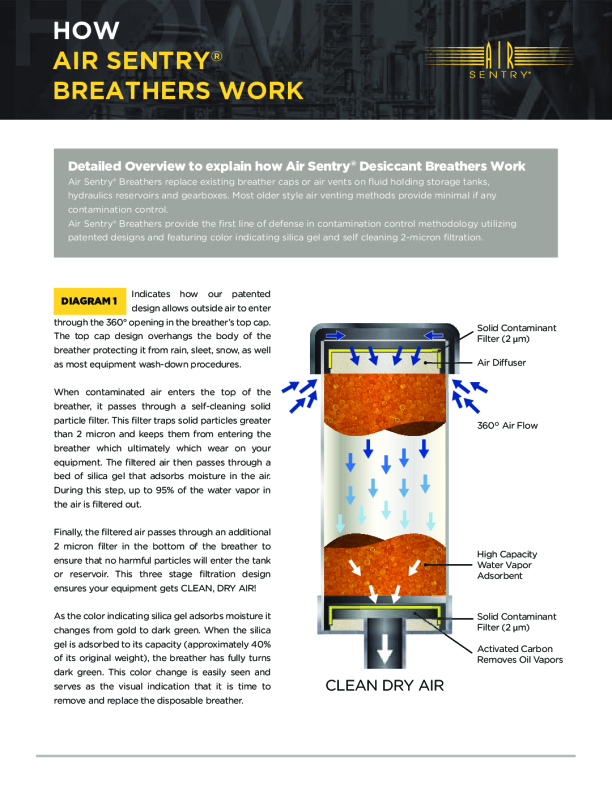

Clear View 360 Degree Design

The clear view 360 degree design makes is easy to inspect the saturation of the color-changing silica gel from a distance. The inert silica gel turns from gold to dark green to visually indicate the adsorption of moisture and confirm the breather is getting the job done.

Air Sentry® - Desiccant Breathers

GUARDIAN® - Desiccant Breathers

Air Sentry Brochures

Filter Documents by Language: